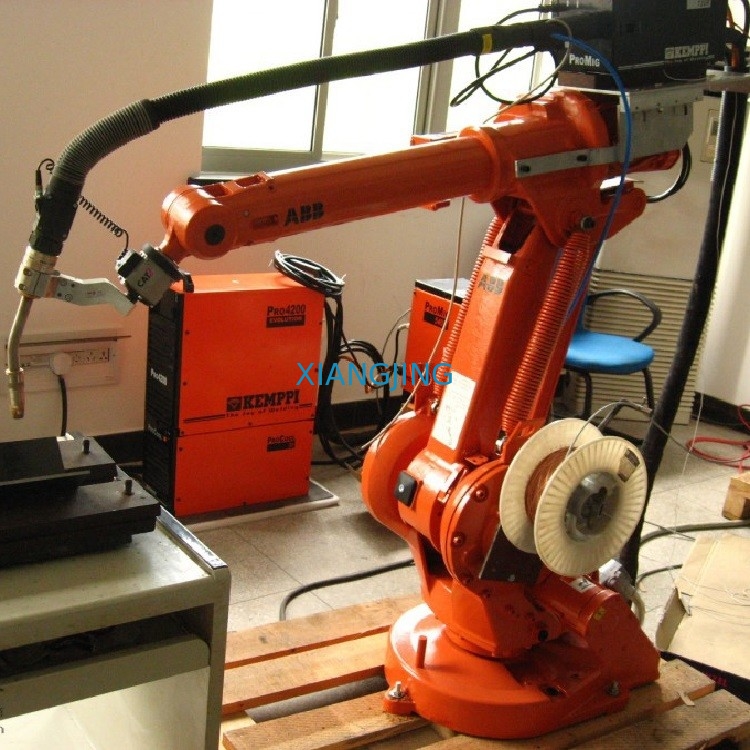

IRB1520 Used ABB Robot With Welder Second Hand Welding Robot Arm

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | ABB |

| Certification: | CE |

| Model Number: | IRB1520 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | negotiable |

| Packaging Details: | ONE Industrial Robots FD-V6S As OTC Welding Equipment Of 7 Axis Robot Arm Robotic Welding Machine packing with fumigation wooden frame. |

| Delivery Time: | 6-8working days |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 999 sets/month |

|

Detail Information |

|||

| Name: | Painting Robot IRB52 6 Axis Cnc Robot Arm And Robot Arm Assembly For Painting Small And Medium Sized Parts In A Wide | Brand: | ABB |

|---|---|---|---|

| Model: | IRB1520 | Production Year: | 2000-2015 |

| Warranty: | 3 Month | Reach: | 1.2m |

| Payload: | 52kg | Reapetability: | 1339 Mm |

| Axis: | 6 | ||

| High Light: | IRB1520 Used ABB Robot,Second Hand welding robot arm,1.2m Reach Used ABB Robot |

||

Product Description

Second hand IRB1520 welding robot arm with welder and welding machine

General Information

|

Classifications

Dimensions

|

Product Description

It includes ABB’s unique integrated paint system, IPS.

- Reliable – A combination of proven technology and well tested innovations

- Fast – High speed in all axes delivering improved cycle times

- Accurate – Outstanding position repeat-ability resulting in high process and product quality

- Flexible – versatile mounting options enabling space saving layouts

- Versatile – wide reach, long stroke and ability to handle large payloads

- Compact – smaller spray booth size and reduced ventilation needs resulting in increased energy efficiency

Compact

The compact design of the IRB 52 means smaller spray-booth sizes, reduced ventilation needs and system energy savings.

Flexible

With its small size and impressive reach (1.2 or 1.45 meters) the IRB 52 is flexible and versatile, while its high speed and accuracy offer short cycle times and high quality painting.

Versatile mounting options allow the IRB 52 to meet your demands for flexible integration and increased production.

The IRB 52 can be easily integrated with a range of process accessories, such as turntables, shuttle tables and conveyor systems. The robot is light weight and very easy to install, program and maintain.

Integrated

The IRB 52 is designed for painting—fully prepared for integrated paint process equipment. It utilizes the powerful and well proven Integrated Process System (IPS) for high speed process control—synchronized with the superior IRC5P motion system.

The IPS system includes color change valves and airand paint regulation, providing accurate process regulation, offering high quality finish and major paint savings.

The combination of proven technology and well-tested innovations offers reliable production and high uptime. The IRB 52 can significantly improve your productivity.

Designed for painting

The IRC5P is the newest generation paint robot control system specifically designed for the paint shop. Key elements of its user friendly interface are the Exi certified FlexPaint pendent with multi-language support, and the customizable PC software for paint cell supervision, RobView 5.

The compact design of the IRB 52 means smaller spray-booth sizes, reduced ventilation needs and system energy savings.

Flexible

With its small size and impressive reach (1.2 or 1.45 meters) the IRB 52 is flexible and versatile, while its high speed and accuracy offer short cycle times and high quality painting.

Versatile mounting options allow the IRB 52 to meet your demands for flexible integration and increased production.

The IRB 52 can be easily integrated with a range of process accessories, such as turntables, shuttle tables and conveyor systems. The robot is light weight and very easy to install, program and maintain.

Integrated

The IRB 52 is designed for painting—fully prepared for integrated paint process equipment. It utilizes the powerful and well proven Integrated Process System (IPS) for high speed process control—synchronized with the superior IRC5P motion system.

The IPS system includes color change valves and airand paint regulation, providing accurate process regulation, offering high quality finish and major paint savings.

The combination of proven technology and well-tested innovations offers reliable production and high uptime. The IRB 52 can significantly improve your productivity.

Designed for painting

The IRC5P is the newest generation paint robot control system specifically designed for the paint shop. Key elements of its user friendly interface are the Exi certified FlexPaint pendent with multi-language support, and the customizable PC software for paint cell supervision, RobView 5.

The IRB 52 comes in two versions:

- IRB 52 / 1.2 m vertical arm

- IRB 52 / 1.45 m vertical arm

![]()

Want to Know more details about this product